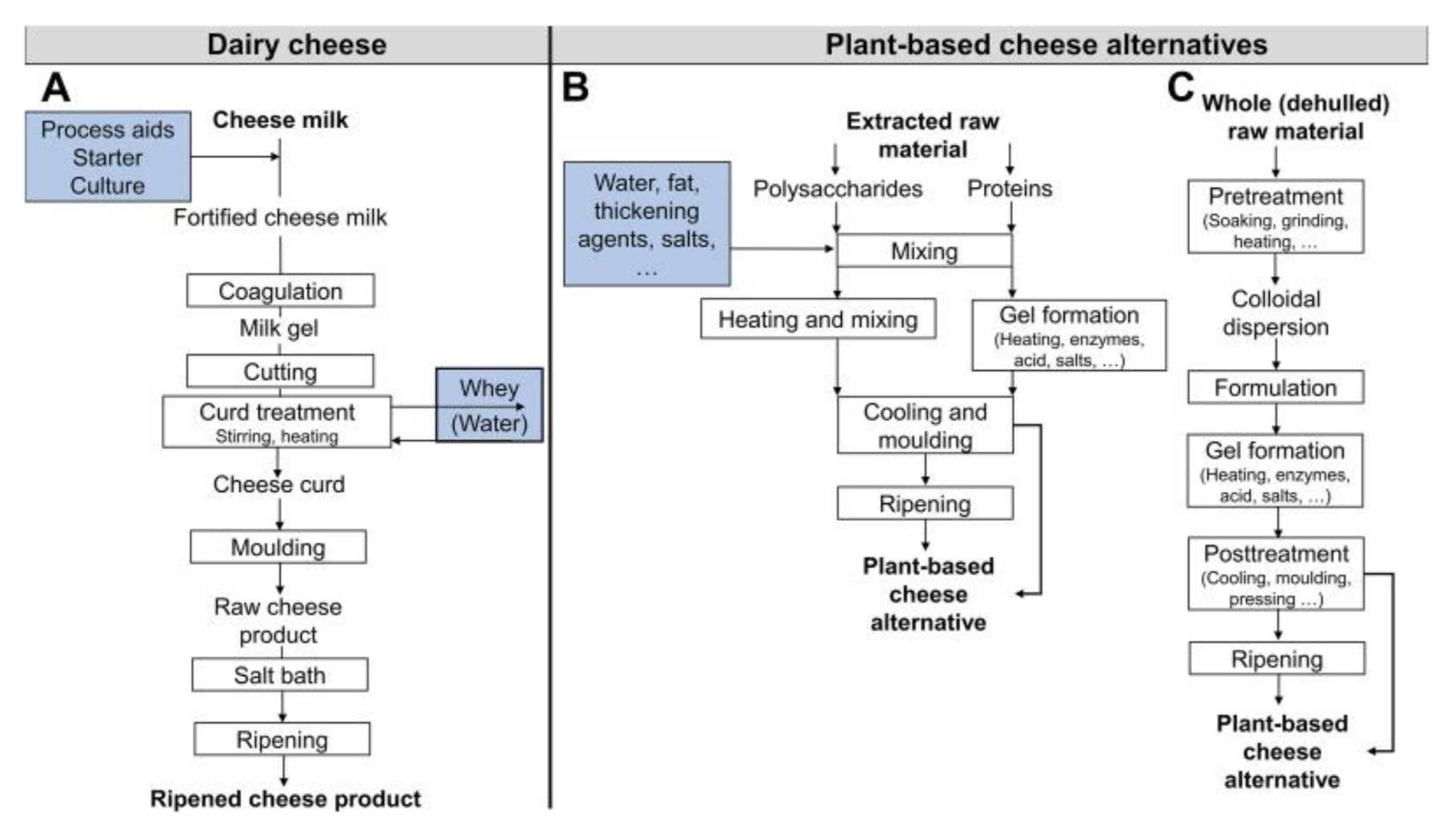

There are two main production methods for plant-based alternatives. These alternatives are produced either with extracted raw materials or with whole raw materials. If the alternative is prepared from extracted raw materials, various components are mixed in the desired proportions before gel formation. Gelatinization is performed to form a solid matrix. Typical gelatinization mechanisms include heat application (e.g., starch gelatinization), precipitation with salts (e.g., altering the electrostatic interactions of soy proteins in tofu production), enzymes (e.g., transglutaminase), and/or acids. Most plant-based cheese alternatives currently available on the market are produced from extracted materials using starch as the main structural component.

When whole plant material is used as the starting material, the entire plant material is ground and soaked. The naturally occurring components of the raw material can function as a gelling agent, or extracted gelling agents can be added, and the same mechanisms applied to products made from extracted materials can be applied. However, among products made from ground whole materials, there are also products that can be considered pastes. Unlike gels, they do not have a network structure, and the body of the product is formed by the presence of solid particles at high density in an aqueous phase, but no cross-linked network structure is formed.

Plant-based cheese alternatives have been found to possess textural quality characteristics ranging from merely acceptable to satisfactory. Studies have shown that the closer a plant-based alternative is to its animal-based reference, the more it will be accepted by consumers. There is a large body of literature on plant-based cheese alternatives produced using plant-based proteins. These proteins have been used either as a pure protein matrix or as a hybrid product with starch as a structuring agent. However, it is known that the number of products containing protein gel among plant-based cheese alternatives currently on the market is limited. Therefore, their nutritional value is lower than that of cheese obtained from dairy products. In terms of functionality, their poor melting behavior has been widely criticized, and some researchers are working to achieve ideal textural properties using entirely plant-based materials to convince critical consumers who prefer to consume dairy products.

Currently, research on technical and functional properties is conducted using common methods for cheese derived from dairy products. The matrix of plant-based cheese alternatives is completely different from that of cheese derived from dairy products.

https://www.sciencedirect.com/science/article/pii/S0958694624001766

Legal Naming

Labeling Regulation Guide Article 12: Products intended for vegan nutrition, made entirely from plant-based ingredients without the use of milk or milk components, may be produced in a way that does not create the perception of cheese in their brand, name, and/or visuals. Statements such as “Suitable for vegetarians/vegans” may be used on the labels of foods intended for vegetarian and vegan consumers. In addition to these statements, terms such as “Plant-based,” “Plant-derived,” or “Contains no animal ingredients” may be used. If foods intended for vegetarian and vegan consumers have similarities in shape, area of use, etc. with animal-based foods such as meat and dairy products, statements such as “Suitable for vegetarians/vegans” should be used; these statements should be in the main field of view with the food’s name, brand, or trade name, in a font size at least as large as the food’s name, and in a background color that contrasts with the background, and easily distinguishable by the consumer, at least the same font size as the food’s name.

https://kms.kaysis.gov.tr/Home/Goster/204259

The Turkish Food Codex Cheese Regulation states that ‘Products that give the impression of cheese by using vegetable oil or other food components cannot be produced.’

https://www.resmigazete.gov.tr/eskiler/2015/02/20150208-16.htm